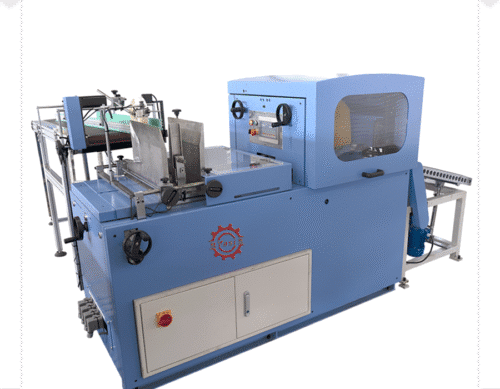

Nombre de la máquina: Línea de producción automática de recopilación y costura automática de HL-Uniplex SX1

Descripción:

Composición de productos:

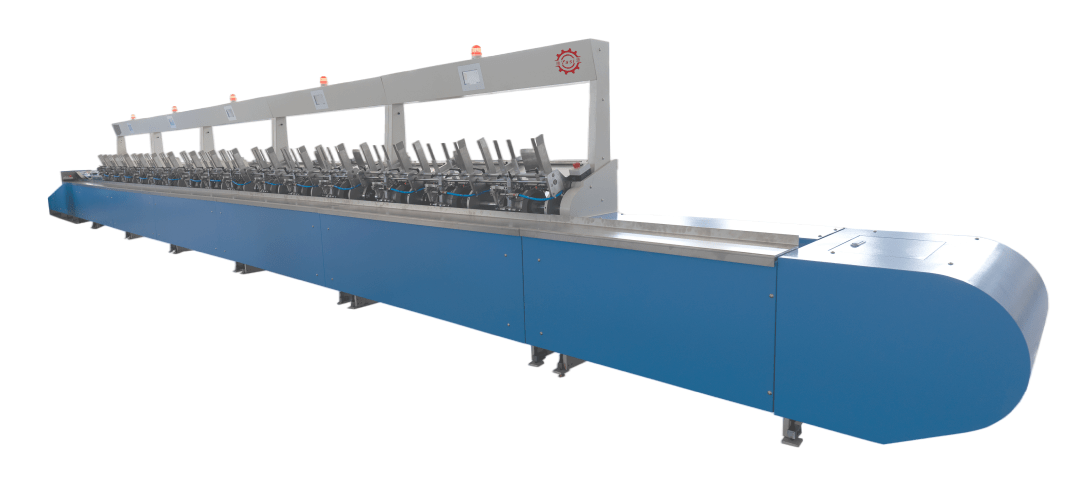

El producto consta de SX220/43.、SX200/51、Máquina de coser libros automática SX NO SPACE con configuración estándar, y múltiples conjuntos de estaciones de clasificación AUSCP PY43 conectadas entre sí (arriba a 48 se pueden conectar estaciones de clasificación, con una configuración estándar de 15 estaciones de clasificación)

Concepto de diseño :

La línea de alzado y cosido de libros es actualmente la forma más rápida de completar los procesos de alzado y cosido de libros en una sola línea de producción., lo que la convierte en la combinación perfecta de máquinas automáticas de clasificación y cosido de libros. Elimina la necesidad de manipulación y almacenamiento manual., ahorra mano de obra y espacio para el traslado, reduce la fatiga del trabajador, mejora la eficiencia de producción, y ahorra costes de producción

Configuración del producto:

1.(SX220/43、SX200/51、Máquina de coser libros SX NO SPACE) con manipulador y una cadena transportadora de alimentación automática AUSCP PS

2.PD 15 estaciones de clasificación y 2 estaciones de mano

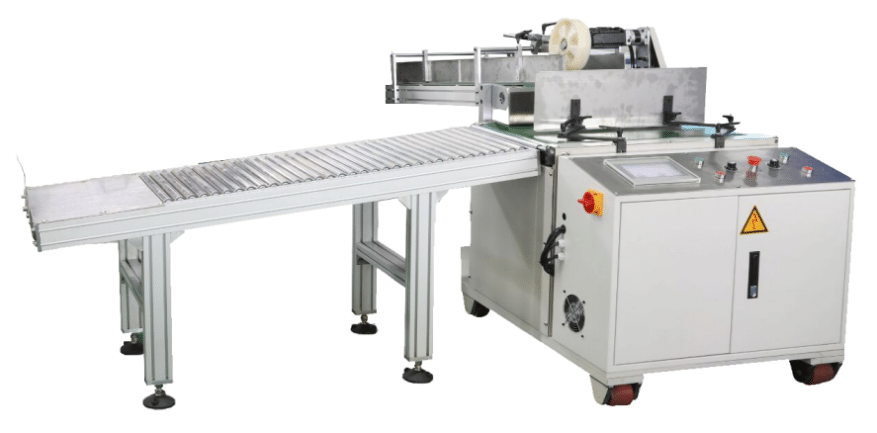

3. DJ43 Apilador receptor de libros

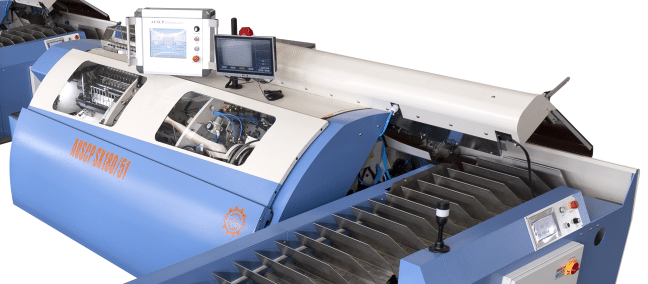

máquina clasificadora:

- Sistema de control inteligente, programable a través del menú La máquina viene de serie con una pantalla táctil a color de 12 pulgadas en un brazo giratorio, que puede controlar el funcionamiento de la máquina, información de alarma, y facilitar la resolución de problemas oportuna para el operador. Es fácil de operar y fácil de aprender.

● La estación de paginación está equipada con sensores para detectar el espesor., páginas vacías o bloqueadas, y transporte, con luces indicadoras para una rápida resolución de problemas

● La estación de paginación está equipada con sensores para detectar el espesor., páginas vacías o bloqueadas, y transporte, con luces indicadoras para una rápida resolución de problemas

● La máquina paginadora tiene funciones continuas de arranque y vaciado., y se alimenta automáticamente según las necesidades de la máquina automática de coser alambre sin intervención manual

● La máquina paginadora adopta un diseño de pegado inferior tipo rodillo., y las páginas del libro corren verticalmente sin fricción durante el funcionamiento rápido

● El canal de transporte adopta un diseño sin fricción tipo tambor para evitar el roce de las páginas y garantizar un transporte sin problemas.

● Cada máquina de coser con alambre está equipada con un canal de almacenamiento. (cadena del tanque) para alimentación bajo demanda y llenado automático de tiempos de inactividad provocados por parada de la máquina paginadora

● Diseño modular, libremente combinable, con un máximo de 48 estación de paginación

máquina de coser libros:

- Alta velocidad y precisión: velocidad máxima de hasta 200 firmas por minuto, con tres cajas de control de levas completamente selladas llenas de aceite lubricante para un funcionamiento suave y duradero El volante impulsa con precisión la alimentación del papel, transmisión, y costura del sillín La firma del libro en el sillín se coloca con precisión a través de una estructura de cinturón sincronizada con tirador

● El poste del libro se posiciona con precisión mediante el calibre de tracción de la estructura de correa síncrona superior e inferior.

● Depuración inteligente: La pantalla táctil a color monitorea toda la producción, incluida la alimentación del papel., transmisión, de coser, y recibiendo, asegurando la calidad de la costura

● Detección de fallos & identificando: Cuando fallas como firmas faltantes, firmas múltiples, apretura, firmas caídas, firmas abreviadas, y se producen firmas rotas, La máquina emitirá una alarma y se detendrá., mientras se muestra la falla

● Función automática de detección de firmas erróneas

● Almacenamiento de memoria: puede almacenar 20 diferentes programas de costura de libros y recuperarlos según sea necesario

● Ajuste automático de la placa: configurando el tamaño de la firma en la pantalla táctil y confirmando el método de paso de página, el sistema de transmisión posiciona automáticamente la cinta transportadora, abre el pasa páginas, ajusta la posición de la cadena de transmisión del sillín fijo y la rueda de aceleración, y ajusta la altura de la plataforma del libro terminado Simple y fácil de aprender, operación rápida, y cambio rápido de placa, lo que mejora la eficiencia de la producción

● Separación de firmas: el soplador y el brazo mecánico separan la firma inferior de la pila, y la ventosa extrae la firma separada del alimentador El brazo mecánico sujeta las firmas del libro al transportador El dispositivo de inclinación ayuda a eliminar rayones en la superficie de la firma

● Cambio de página automático: el volteador de páginas está equipado con cuatro dispositivos de succión de vacío programables, tanto el lado superior como el inferior, que puede realizar 4+4 pasar página al vacío, and can handle signatures with even or uneven tops and bottoms It can automatically flip through sets of pages, paginas sueltas, páginas sin bordes largos o cortos, y firma con grosor desigual. También puede pasar páginas de firmas con bordes de más de 8 mm de largo o cortos.

● Transmisión de firma: the signature is placed on the conveying saddle after being turned and is pushed by the conveyor chain hook The acceleration wheel sends the signature into the active sewingsaddle, Y la velocidad de la rueda de aceleración se ajusta automáticamente según la velocidad de la máquina.

● Separación automática de firmas y corte de hilos.: el dispositivo automático de separación de firmas y corte de hilo (corta el exceso de hilo a unos 8-10 mm para facilitar la unión) Puede separar las firmas de libros una por una según la configuración., independientemente del número de firmas en el libro

● Bloqueo plano: utiliza agujas finas ultracortas (¢16mm) con un espacio de puntada estrecho (19milímetro) para hacer el producto más plano y menos propenso a fugas de pegamento, Garantiza una costura de libros de alta calidad. El dispositivo de costura consta de un equipo tipo caja de levas., que no sólo reduce el ruido sino que también prolonga la vida útil de la leva

● Equipado con una máquina apiladora de libros., Puede apilar libros con encuadernación cerrada hasta una altura de 120 mm., y transportarlos cuidadosamente a la plataforma de recolección de libros para facilitar su paletización.;

● Lubricación bajo demanda: equipado con sistema de lubricación de suministro de aceite centralizado, oil pressure alarm and oil storage device When the machine is in operation, El lubricante se suministra con precisión a través de la tubería donde sea necesario y de manera oportuna.

产品参数 :

| máquina clasificadora:

|

|||

|

máx.. velocidad de funcionamiento

|

6000 ciclos por hora | máx.. tamaño (Alto x Largo) | 430x285mm |

|

Publicaciones emparejadas

|

12-48 firmas | mínimo. tamaño (Alto x Largo) | 148x95mm |

|

máquina de coser libros:

|

|||

|

máx.. velocidad de funcionamiento

|

220

Signatures per minute |

Firma mínima cosida | 2 firmas |

|

máx.. tamaño de la firma (Alto x Largo)

|

430x320mm |

Page Turner Qty |

4 arriba + 4 bottom |

|

mínimo. tamaño de la firma (Alto x Largo)

|

148x95mm | Thread hook diameter | ¢1,6mm |

| máx.. Número de posiciones de puntada | 10 |

Grosor de firma única

|

0.5~1,5 mm |

|

Longitud de puntada

|

19 milímetro | ||

|

Whole machine:

|

|||

|

Consumo de energía |

20kilovatios | Consumo de aire (suministro externo) | máximo. 1.0m3/min a 8bar |

|

Peso neto

|

8500Kg | voltaje estándar | 380V/220V 50Hz trifásico

400V, 50 Hz, 3 etapas |

|

Dimensiones (largo x ancho x alto)

|

23550×6300×1850mm | ||

|

LHS máx.. tamaño 320 430 1.5milímetro mínimo. tamaño 95 148 0.5milímetro |

AUSCP Uniplex sx1

|

||

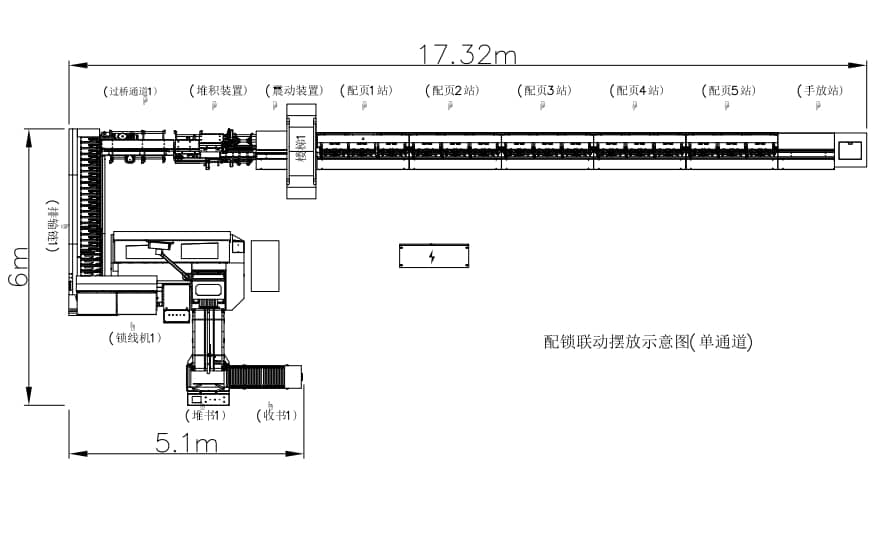

Equipment installation plan:

Datos detallados:

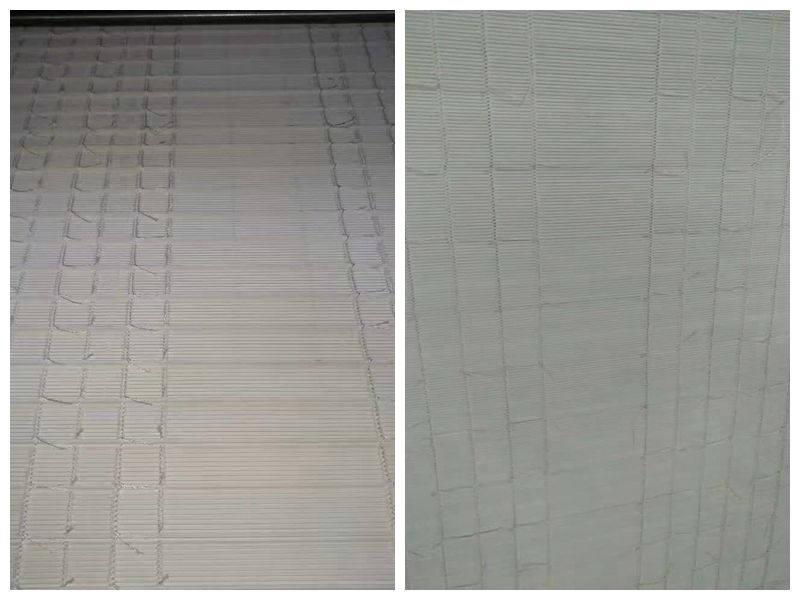

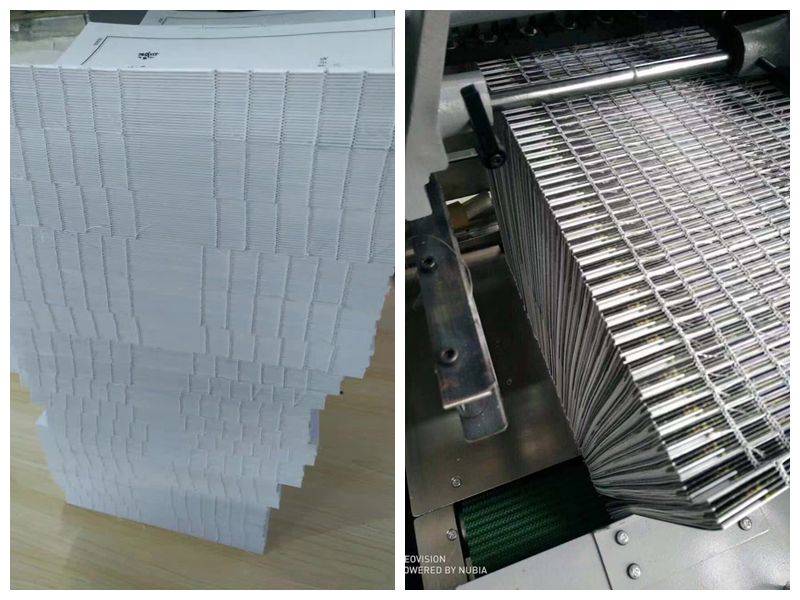

Sample for HL-Uniplex sx1 Automatic Collating and Book Sewing Production Line

Video

Sobre nosotros

Zhejiang Haoly limitada combina precio extremadamente competitivo, Tecnologías innovadoras y larga experiencia exportadora en la máquina de post-prensa., impresora,y máquina de embalaje, y máquina de impresión rápida. Somos su mejor selección para las industrias de impresión y embalaje..

En los últimos diez años, Lanxi Jinhua Machine Company se centra en la máquina para libros de ejercicios cosidos con alambre, rayado y láminas, libro de tapa blanda y dura. Puede fabricar una máquina para hacer libros de ejercicios completamente automática, libro de ejercicios maquina regla, máquina de coser libros, carcasa en maquina, máquina para hacer tapa dura, recortadora de tres lados, máquina de coser silla de montar, máquina de encuadernación de pegamento, y otra máquina de post prensa.

También podemos proporcionar tipos de máquinas de impresión y embalaje., como

1. máquina de post prensa: cortadora de papel, maquina laminadora, maquina troqueladora y plegadora, máquina de estampado en caliente, máquina plegadora de papel, clasificadora de papel, máquina perforadora de papel, máquina de ojales

2. Impresora: Máquina de impresión en offset, máquina de pre-prensa, Máquina de impresión flexográfica, máquina de impresión de tarjetas

3. máquina de impresión rápida: pequeño cortador de papel, máquina de plegado digital, pequeña máquina de encuadernación con pegamento.

4. Máquina para fabricar productos de papel: carpeta encoladora, máquina de caja de papel, maquina para hacer bolsas de papel, máquina de vasos de papel, maquina para hacer sobres

Somos una fábrica y un fabricante real que opera en la línea de máquinas de postimpresión y máquinas de embalaje por más de 10 años.

1. 30 años de experiencia en producción con buena calidad. Todas nuestras máquinas tienen certificado CE.

2. Precio competitivo en el mismo nivel de calidad de las cortadoras de papel..

3. Servicio cuidadoso de preventa y posventa. Alguna pregunta, Por favor, siéntase libre de contactarnos.

Para la mayoría de los pedidos, condiciones de pago es 30% T/T por adelantado antes de la producción, el balance 70% debe ser pagado antes de la entrega. Y también aceptamos otras formas como L/C, unión occidental, etc..

1. Uausly ,la mayoría de las máquinas son estables y fáciles de operar, Con la ayuda de videos e instrucciones., usted puede aprender rápidamente cómo operar.

2. Si aún no puede operar, Ofrecemos capacitación en línea e instrucción en video

3. Si necesita enviar un ingeniero, por favor contáctenos para una consulta detallada

Máquina Haoly

Máquina Haoly