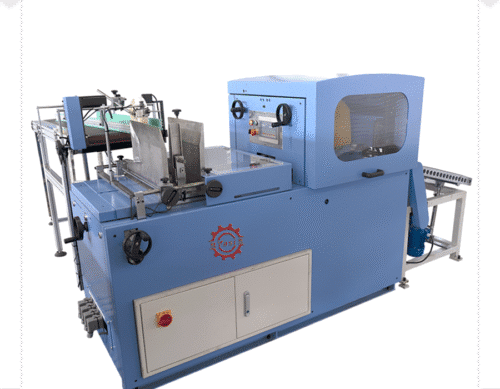

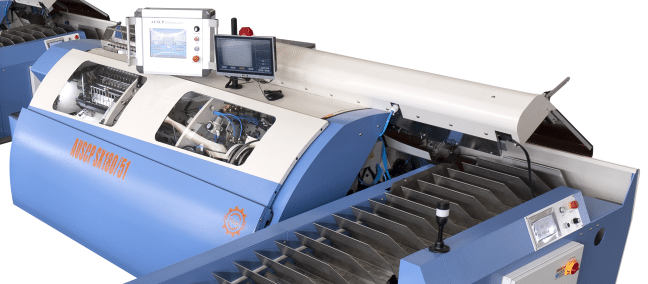

マシン名: HL-Multiplex sx2 Automatic Collating and Book Sewing Production Line

説明:

Product composition:

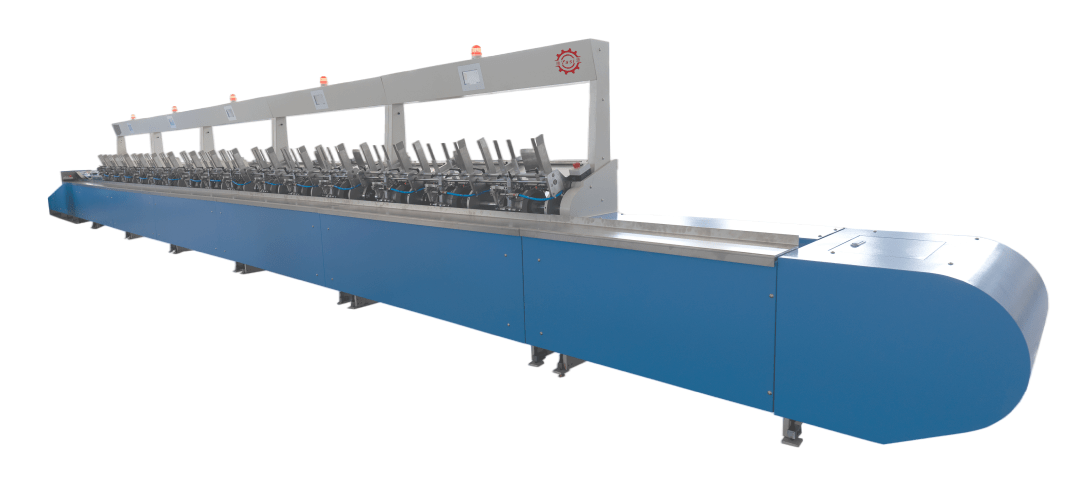

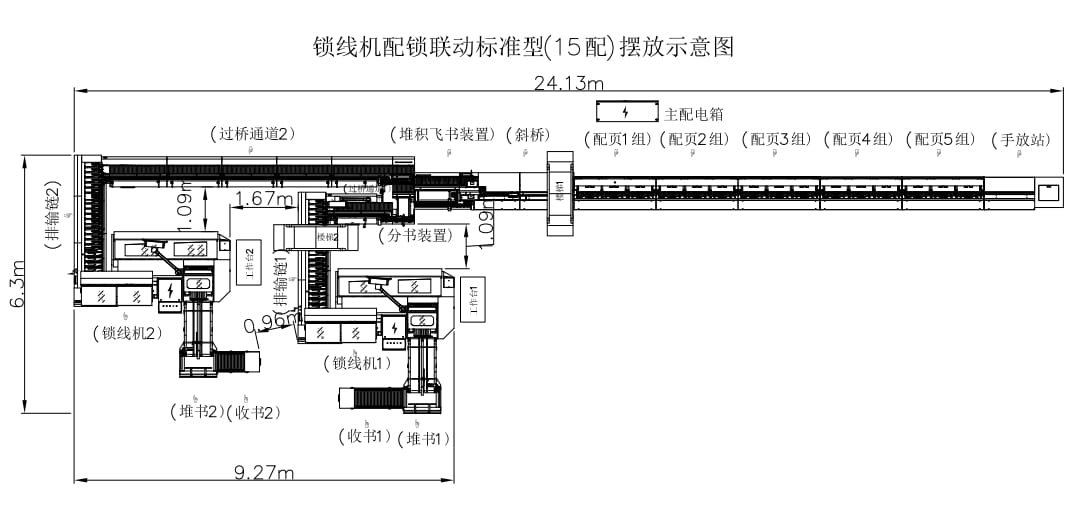

This production line is configured with up to three (SX220/43, SX200/51, SX NO SPACE) fully automatic book sewing machines, and multiple sets of PY43 collating station linked together (up to 48 collating stations can be connected, with a standard configuration of 15 collating stations)

Design concept:

The collating and book sewing line is currently the fastest production line to simultaneously complete collating and book sewing processes, making it the perfect combination of automatic collating and automatic book sewing machines. It eliminates the involvement of manual handling and storage, saves labor and space for transfer, reduces worker fatigue, improves production efficiency, and saves production costs.

Product configuration:

1.One SX220/43、SX200/51、SX NO SPACE)book sewing machine with manipulator and one AUSCP PS Automatic feeding conveyor chain

PS 15 collation stations and 2 hand stations

3. DJ43 Book receiving stacker

Collating machine:

- Intelligent control system, programmable via default menu The machine comes standard with a 12-inch color touch screen on a rotating arm, which can control machine operation, alarm information, and facilitate timely troubleshooting for the operator It is easy to operate and simple to learn

● The collate station is equipped with sensors for detecting missing signatures, multi-signatures, jams, dropped signatures as well as indicator lights for quick troubleshooting

● The collating station will collate disordered signatures into predetermined sequence and stack up to a maximum 90mm high Then transport it to distribution station to allocate signatures to different sewing machines accordingly

● The collating machine has continuous start-up and emptying functions, and automatically feeds according to the needs of the automatic wire stitching machine without manual intervention

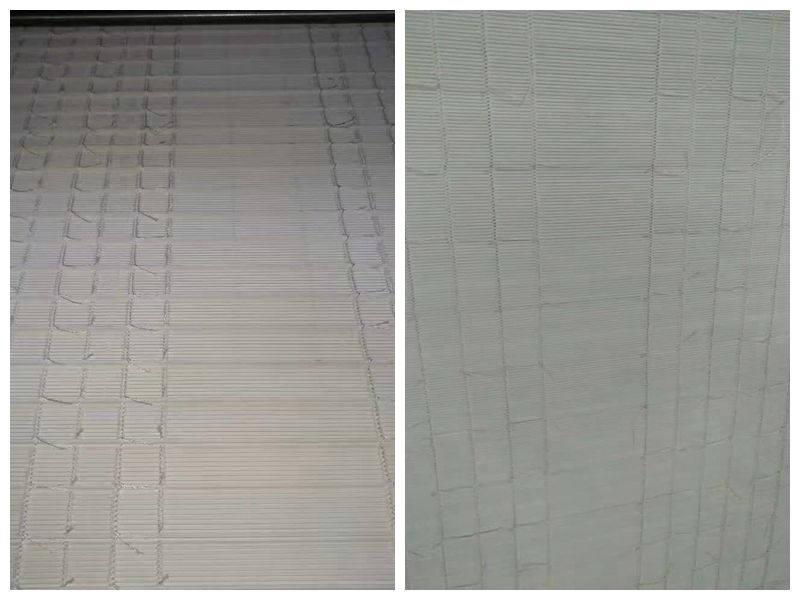

● The collating machine adopts a roller-type pasting design, signatures run vertically & frictionlessly during rapid operation

● The transport channel adopts a drum-type frictionless design to prevent pages from being rubbed and ensure smooth transport

● Each sewing machine is equipped with a storage channel (tank tread) for feeding on demand and automatic filling of downtime caused by unexpected stoppage

● Modular design, freely combinable, with a maximum of 48 collating station

ブックミシン:

- High speed and precision: maximum speed of up to 220 signatures per minute, with three fully sealed cam control boxes filled with lubricant for smooth and durable operation The flywheel accurately drives paper feeding, conveying, and saddle stitching The book signature on the saddle is precisely positioned through the synchronized belt structure with a puller

● Intelligent control system: Colored touchscreen monitors the entire production including paper feeding, conveying, lockstitching, and receiving, ensuring the quality of lockstitching

● Fault detection & identifying: When faults such as missing signatures, multi-signatures, jams, dropped signatures, shortened signatures, and broken signatures occur, the machine will alarm and pause, while displaying the fault

● Automatic mis-signature detection function

Memory storage: can store up to 20 different book sewing programs and recall as needed

● Automatic template adjustment: by setting the size of the signature on the touch screen and confirming the page-turning method, the transmission system automatically positions the conveyor belt, opens the page-turner, adjusts the position of the fixed saddle drive chain & acceleration wheel, and prepares the height of the finished book platform Simple and easy to learn, fast operation, and quick template switching, which improves production efficiency

● Signature separation: the blower and mechanical arm separate the bottom signature from the pile, and the suction cup extracts the separated signature from the feeder The mechanical arm clamps the book signatures to the conveyor The tilting device helps eliminate scratches on the surface of the signature

● Automatic page-turning: the page-turner is equipped with four programmable vacuum suction cups at both the upper and lower sides, which can perform 4+4 vacuum page-turning, and can handle signatures with even or uneven header and footer It can automatically flip through sets of pages, loose pages, pages without long or short edges, and unevenly thick signatures It can also turn pages of signatures with edges over 8mm difference

● Signature conveying: the signature is placed on the conveying saddle after being turned and is pushed by the conveyor chain The acceleration wheel sends the signature into the active lockstitch saddle, and the speed of the acceleration wheel automatically adjusts according to the speed of the machine

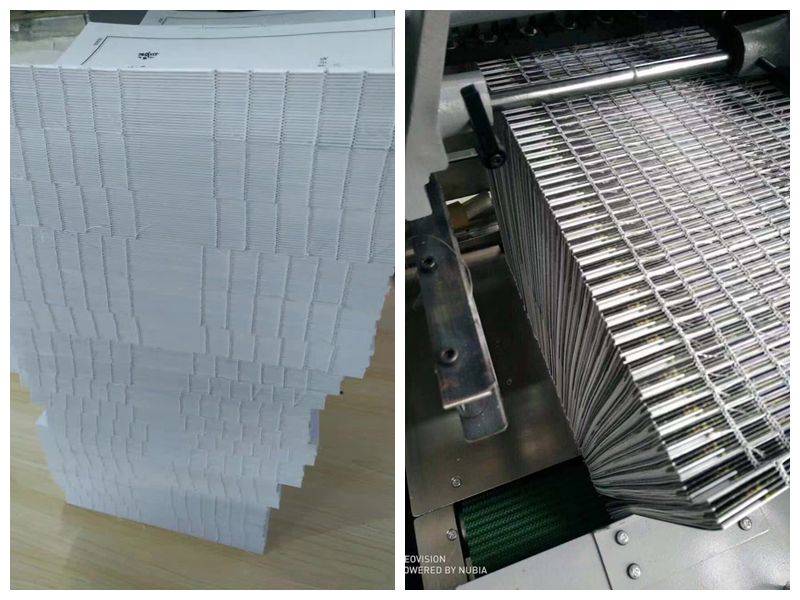

● Automatic signature separation and thread cutting: the automatic signature separation and thread cutting device (cuts the excess thread to about 8-10mm for easy binding/gluing) can separate the book signatures one by one according to the setting, regardless of the number of signatures in the book

● Flatlock: uses fine ultra-short needles (¢16mm) with a narrow stitch spacing (19んん) to make the product firmer & fatter and less prone to glue leakage, ensuring high-quality book sewing The lockstitch device consists of integrated control cam box, which not only reduces noise but also extends the longevity of the cam

● Equipped with a book stacking machine, it can stack books with locked binding up to a height of 120mm, and neatly convey them to the book collection platform for easy palletizing;

● Lubrication on demand: equipped with centralized oil supply lubrication system, oil pressure alarm and oil storage device When the machine is in operation, lubricant is precisely supplied through the pipe to wherever necessary in a timely manner

Technical Data:

|

Collating machine:

|

|||

|

マックス. operating speed

|

6000 1時間あたりのサイクル数 | マックス. サイズ (高さ×長さ) | 430x285mm |

|

Paired posts

|

12-48 signatures | 分. サイズ (高さ×長さ) | 148x95mm |

|

ブックミシン:

|

|||

|

マックス. operating speed

|

220 Signatures per minute | 最小サインが縫い付けられています | 2 signatures |

|

マックス. signature size (高さ×長さ)

|

430×320mm | 利用可能な開口部 | 4 トップ + 4 bottom |

|

分. signature size (高さ×長さ)

|

148x95mm | Thread hook diameter | ¢1.6mm |

|

マックス. number of stitch positions

|

10 | 単一署名の厚さ | 0.5~1.5 mm |

|

縫い目長さ

|

19 んん | ||

|

Whole machine: |

|||

|

Power consumption

|

20キロワット | 空気消費量 (外部電源) | 最大. 1.0m3/分および8bar |

|

正味重量

|

8500Kg | 標準電圧 | 400V, 50 Hz, 3 フェーズ |

|

寸法 (length x width x height) |

23550×6300×1850mm |

||

|

L H S マックス. サイズ 320 430 1.5んん |

AUSCP Multiplex sx2

|

||

Sample for HL-Uniplex sx1 Automatic Collating and Book Sewing Production Line

ビデオ

私たちについて

浙江 Haoly Limited 非常に競争力のある価格を組み合わせる, ポストプレス機械における革新的な技術と長年の輸出経験, 印刷機,と包装機, 印刷および包装業界に最適な選択肢です。.

過去10年間で, 蘭渓金華機械会社はワイヤーステッチ問題集の機械に注力, 罫線とシーチング, ソフトカバーとハードカバーの本。全自動練習帳作成機を製造できます。, 練習帳罫引き機, 本ミシン, 機械内のケーシング, ハードカバー製造機, 三面トリマー, 中綴じ機, 糊付け製本機, およびその他のポストプレス機.

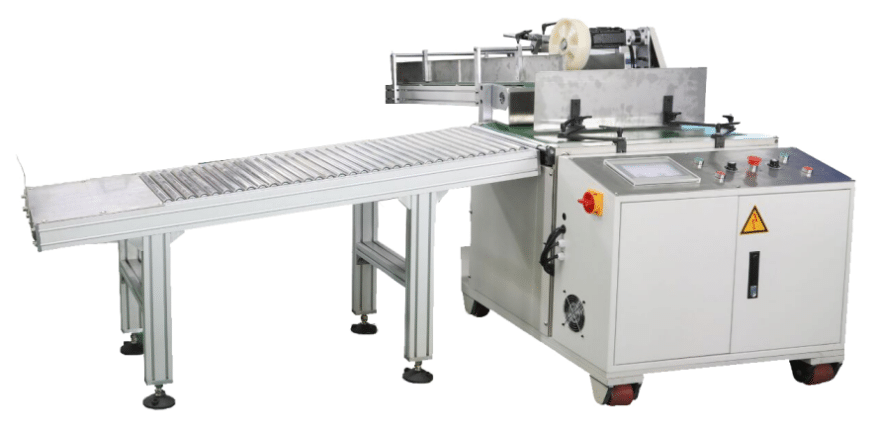

各種印刷機や包装機も提供できます, のような

1. ポストプレス機: 紙裁断機, ラミネート機, 折り目付けおよびダイカットマシン, ホットスタンプ機, 紙折り機, 紙丁合機, 紙パンチングマシン, アイレットマシン

2. 印刷機: オフセット印刷機, プリプレス機, フレキソ印刷機, カード印刷機

3. クイック印刷機: 小さなペーパーカッター, デジタル折り目付け機, 小型糊付け製本機.

4. 紙製品製造機: 糊付けフォルダー, 紙箱製造機, 紙袋機械, 紙コップ機械, 封筒製造機

当社は実際の工場およびメーカーであり、ポストプレス機およびパッケージ機のラインを以上の価格で取引しています。 10 年.

1. 30 長年にわたる高品質の生産経験. 当社のすべてのマシンはCE証明書を取得しています.

2. 断裁機と同レベルの品質で競争力のある価格.

3. 思慮深い販売前および販売後のサービス. 質問は, お気軽にお問い合わせください.

ほとんどの注文に対して, 支払い条件は 30% 生産前に事前にT / T, バランス 70% 配達前に支払う必要があります. また、L/Cなどの他の方法も受け入れます, ウェスタンユニオンなど.

1. オースリー ,ほとんどの機械は安定していて操作が簡単です, ビデオと説明書の助けを借りて, すぐに操作方法を学ぶことができます.

2. それでも操作できない場合, オンライントレーニングとビデオ指導を提供しています

3. エンジニア派遣が必要な場合, 詳細なご相談はお問い合わせください

ハオリマシン

ハオリマシン