기계 이름: HL-Multiplex sx2 Automatic Collating and Book Sewing Production Line

설명:

Product composition:

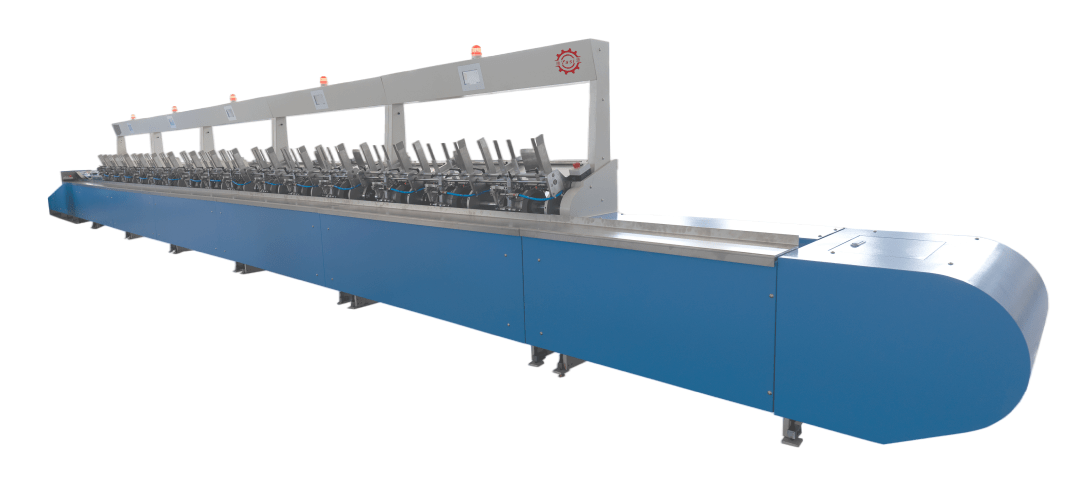

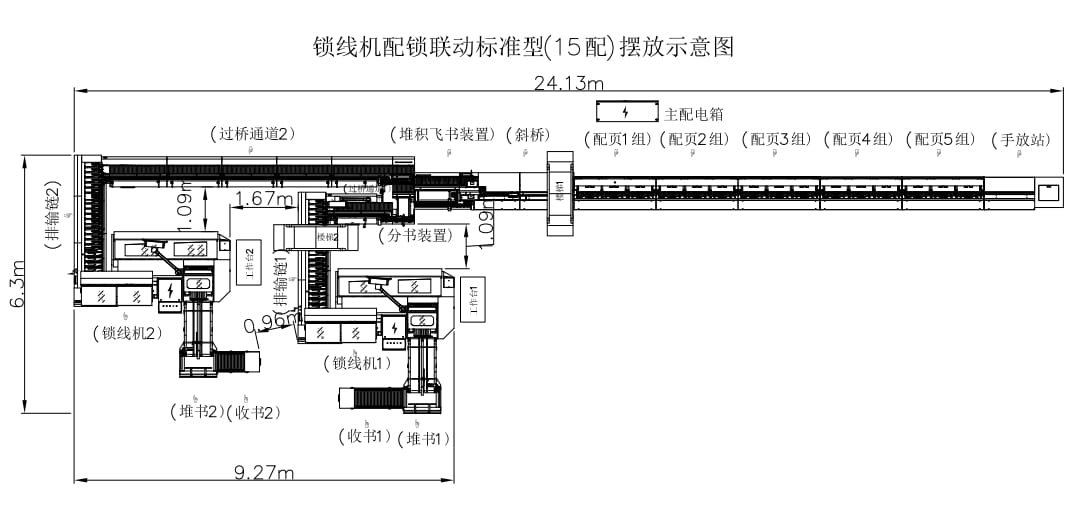

This production line is configured with up to three (SX220/43, SX200/51, SX NO SPACE) fully automatic book sewing machines, and multiple sets of PY43 collating station linked together (up to 48 collating stations can be connected, with a standard configuration of 15 collating stations)

Design concept:

The collating and book sewing line is currently the fastest production line to simultaneously complete collating and book sewing processes, making it the perfect combination of automatic collating and automatic book sewing machines. It eliminates the involvement of manual handling and storage, saves labor and space for transfer, reduces worker fatigue, improves production efficiency, and saves production costs.

Product configuration:

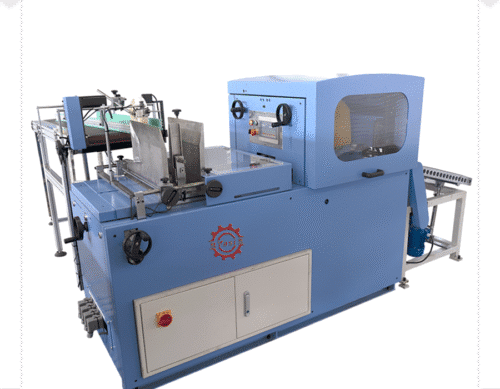

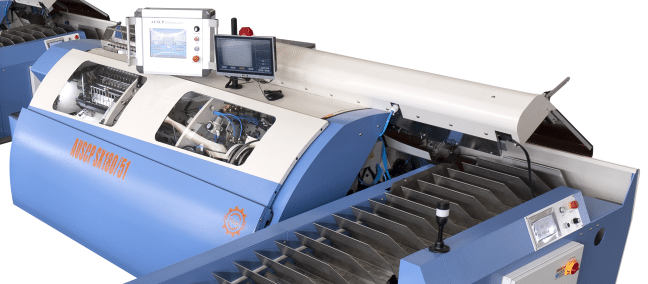

1.One SX220/43、SX200/51、SX NO SPACE)book sewing machine with manipulator and one AUSCP PS Automatic feeding conveyor chain

PS 15 collation stations and 2 hand stations

3. DJ43 Book receiving stacker

Collating machine:

- Intelligent control system, programmable via default menu The machine comes standard with a 12-inch color touch screen on a rotating arm, which can control machine operation, alarm information, and facilitate timely troubleshooting for the operator It is easy to operate and simple to learn

● The collate station is equipped with sensors for detecting missing signatures, multi-signatures, jams, dropped signatures as well as indicator lights for quick troubleshooting

● The collating station will collate disordered signatures into predetermined sequence and stack up to a maximum 90mm high Then transport it to distribution station to allocate signatures to different sewing machines accordingly

● The collating machine has continuous start-up and emptying functions, and automatically feeds according to the needs of the automatic wire stitching machine without manual intervention

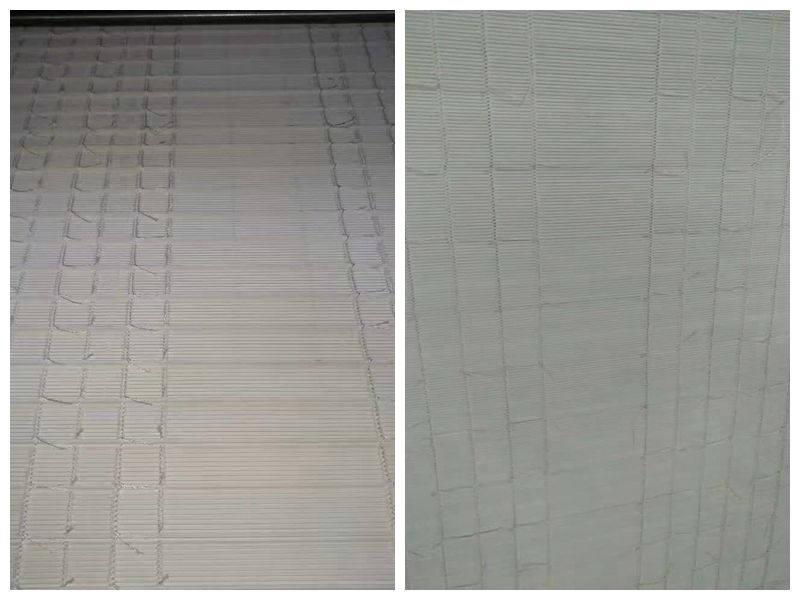

● The collating machine adopts a roller-type pasting design, signatures run vertically & frictionlessly during rapid operation

● The transport channel adopts a drum-type frictionless design to prevent pages from being rubbed and ensure smooth transport

● Each sewing machine is equipped with a storage channel (tank tread) for feeding on demand and automatic filling of downtime caused by unexpected stoppage

● Modular design, freely combinable, with a maximum of 48 collating station

Book sewing machine:

- High speed and precision: maximum speed of up to 220 signatures per minute, with three fully sealed cam control boxes filled with lubricant for smooth and durable operation The flywheel accurately drives paper feeding, conveying, and saddle stitching The book signature on the saddle is precisely positioned through the synchronized belt structure with a puller

● Intelligent control system: Colored touchscreen monitors the entire production including paper feeding, conveying, lockstitching, and receiving, ensuring the quality of lockstitching

● Fault detection & identifying: When faults such as missing signatures, multi-signatures, jams, dropped signatures, shortened signatures, and broken signatures occur, the machine will alarm and pause, while displaying the fault

● Automatic mis-signature detection function

Memory storage: can store up to 20 different book sewing programs and recall as needed

● Automatic template adjustment: by setting the size of the signature on the touch screen and confirming the page-turning method, the transmission system automatically positions the conveyor belt, opens the page-turner, adjusts the position of the fixed saddle drive chain & acceleration wheel, and prepares the height of the finished book platform Simple and easy to learn, fast operation, and quick template switching, which improves production efficiency

● Signature separation: the blower and mechanical arm separate the bottom signature from the pile, and the suction cup extracts the separated signature from the feeder The mechanical arm clamps the book signatures to the conveyor The tilting device helps eliminate scratches on the surface of the signature

● Automatic page-turning: the page-turner is equipped with four programmable vacuum suction cups at both the upper and lower sides, which can perform 4+4 vacuum page-turning, and can handle signatures with even or uneven header and footer It can automatically flip through sets of pages, loose pages, pages without long or short edges, and unevenly thick signatures It can also turn pages of signatures with edges over 8mm difference

● Signature conveying: the signature is placed on the conveying saddle after being turned and is pushed by the conveyor chain The acceleration wheel sends the signature into the active lockstitch saddle, and the speed of the acceleration wheel automatically adjusts according to the speed of the machine

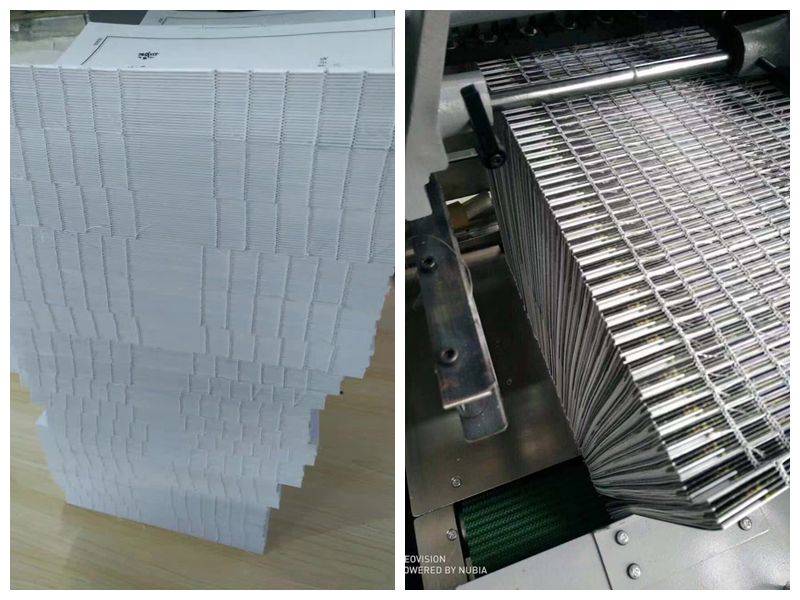

● Automatic signature separation and thread cutting: the automatic signature separation and thread cutting device (cuts the excess thread to about 8-10mm for easy binding/gluing) can separate the book signatures one by one according to the setting, regardless of the number of signatures in the book

● Flatlock: uses fine ultra-short needles (¢16mm) with a narrow stitch spacing (19mm) to make the product firmer & fatter and less prone to glue leakage, ensuring high-quality book sewing The lockstitch device consists of integrated control cam box, which not only reduces noise but also extends the longevity of the cam

● Equipped with a book stacking machine, it can stack books with locked binding up to a height of 120mm, and neatly convey them to the book collection platform for easy palletizing;

● Lubrication on demand: equipped with centralized oil supply lubrication system, oil pressure alarm and oil storage device When the machine is in operation, lubricant is precisely supplied through the pipe to wherever necessary in a timely manner

Technical Data:

|

Collating machine:

|

|||

|

맥스. operating speed

|

6000 시간당 사이클 | 맥스. 크기 (H x L) | 430x285mm |

|

Paired posts

|

12-48 signatures | 최소. 크기 (H x L) | 148x95mm |

|

Book sewing machine:

|

|||

|

맥스. operating speed

|

220 Signatures per minute | Min signature sewed | 2 signatures |

|

맥스. signature size (H x L)

|

430x320mm | Available openings | 4 맨 위 + 4 bottom |

|

최소. signature size (H x L)

|

148x95mm | Thread hook diameter | ¢1.6 mm |

|

맥스. number of stitch positions

|

10 | Single signature thickness | 0.5~1.5 mm |

|

Stitch lenght

|

19 mm | ||

|

Whole machine: |

|||

|

Power consumption

|

20kw | Air consumption (external supply) | 최대. 1.0m3/min at 8bar |

|

순중량

|

8500킬로그램 | Standard voltage | 400V, 50 헤르츠, 3 phases |

|

치수 (length x width x height) |

23550×6300×1850mm |

||

|

L H S 맥스. 크기 320 430 1.5mm |

AUSCP Multiplex sx2

|

||

Sample for HL-Uniplex sx1 Automatic Collating and Book Sewing Production Line

동영상

회사 소개

절강 Haoly 제한 매우 경쟁력있는 가격을 결합, 혁신적인 기술과 포스트 프레스 기계의 오랜 수출 경험, 인쇄기,및 포장 기계, 및 빠른 인쇄기. 우리는 인쇄 및 포장 산업을 위한 최고의 선택입니다..

지난 10년 동안, Lanxi Jinhua Machine Company는 와이어 스티치 연습장 기계에 집중하고 있습니다., 통치 및 시트, 연약하고 단단한 표지 책. 기계를 만드는 가득 차있는 자동적인 연습장을 제조할 수 있습니다, 연습장 판결 기계, 책 재봉틀, 기계 케이싱, 하드 커버 만드는 기계, 3면 트리머, 중철기, 접착제 바인딩 기계, 그리고 다른 포스트 프레스 머신.

우리는 또한 인쇄 및 포장 기계의 종류를 제공할 수 있습니다, ~와 같은

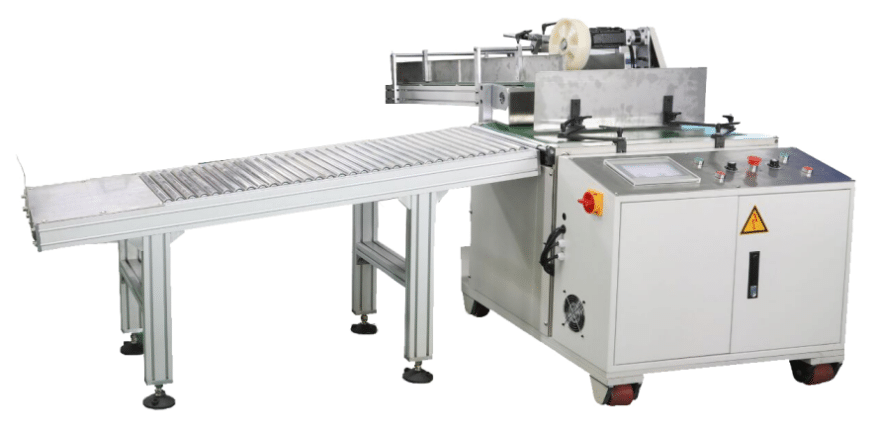

1. 포스트 프레스 기계: 종이 절단기, 라미네이팅 기계, 주름 및 다이 커팅 머신, 핫 스탬핑 기계, 종이접기, 종이 분류 기계, 종이 펀칭기, 작은 구멍 기계

2. 인쇄기: 오프셋 인쇄기, 프리 프레스 기계, 플렉소 인쇄기, 카드 인쇄기

3. 빠른 인쇄기: 작은 종이 절단기, 디지털 주름잡는 기계, 작은 접착제 바인딩 기계.

4. 제지 기계: 접착제 폴더, 종이 상자 기계, 종이 봉지 기계, 종이컵 기계, 봉투 만드는 기계

우리는 후가공 기계 및 패키지 기계 라인에서 거래하는 실제 공장 및 제조업체입니다. 10 연령.

1. 30 좋은 품질을 가진 수년간의 생산 경험. 우리의 모든 기계에는 CE 인증서가 있습니다..

2. 제지 기계와 동일한 수준의 품질로 경쟁력 있는 가격.

3. 사려 깊은 사전 판매 및 판매 후 서비스. 질문, pls는 저희에게 연락 주시기 바랍니다.

대부분의 주문, 지불 조건은 30% 생산 전에 미리 T/T, 균형 70% 배달 전에 지불해야합니다. 그리고 L/C와 같은 다른 방법도 허용합니다., 웨스턴 유니온 등.

1. 유어스리 ,대부분의 기계는 안정적이고 작동하기 쉽습니다., 비디오 및 지침의 도움으로, 조작 방법을 빠르게 배울 수 있습니다..

2. 여전히 작동할 수 없는 경우, 우리는 온라인 교육 및 비디오 교육을 제공합니다

3. 엔지니어 파견이 필요한 경우, 자세한 상담은 연락주세요

하올리 머신

하올리 머신