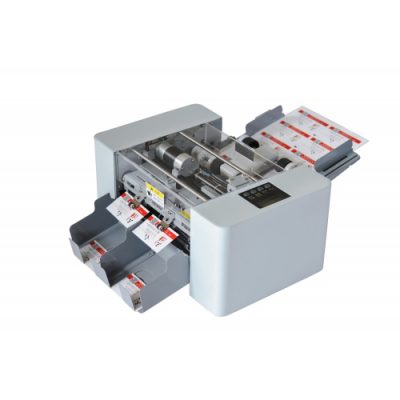

HL-CP A4 PVC card offset press Machine The thickness of paper range is wide. minimum thickness is 280g, maximum thickness is 1300g;Because of precise whorl slice adjustment system adjust the location of image freely even when the machine keeps working; It adopts four clusters of ink rollers and double side plates,so that the printing will be more average .And easy for full printing and registration; Separate ink-water, water and ink feeding adopts separate speed shift control system. Continuous water feeding system makes it easy for operation and adjust ink-water balance.

HL-CP A4 PVC card offset press Machine

Main Function:

1. PVC materials’ color printing.

2. Color printing for all kinds of paper which is more than 280g.

3. Color printing for labels, tags, cardboard and so on.

4. Smart cards, such as VIP card, IC card, ID card, induction card, traffic card and so on.

5. Making printing proof for exquisite packing boxes, such as medicine boxes, food packaging boxes, cigarette boxes, cosmetic boxes and so on.

Main features:

1. The original automatic suction feeder system ensures paper feeding balanceable and smooth.

2. The paper bridge with several sets of rolling bearings ensures steady paper transfer.

3. The special automatic electro-optical modulation measurement ensures reliability of the machine.

4. The machine has accurate front guide and side guide. So, even printing abnormal paper the registration is still accurate.

5. Under the situation of automatic ink feeding, Ink &water is Balance and steady. The printing color is steady. Automatic cleaning device clear up the ink roller, and exchange color quickly and conveniently. The printing quality is steady and Tidy.

6. Pressure adopts cam gear control system that ensures heavy printing pressure and excellent stability.

7. The water roller adopts special material and special disposal so that the water feeding is well-distributed.

8. The special electroplate on the surface of the plate roller, rubber roller and impression roller makes it more durable and wearable, hard for distortion.

9. Advanced rubber roller array system and automatic adjustment in both side of robber roller ensures ink transfer and ink riding more quickly, average ink feeding and excellent printing quality.

Technical description:

| Max.Sheet Sizes | 220×305(mm) |

| Min.Sheet sizes | 90×150(mm) |

| Max.Printing area | 215×300(mm) |

| Printing paper thickness | 0.3-1.5(mm) |

| Printing plate size | 300×310(max)×0.15 |

| Rubber cloth size | 345×315×1.95(mm) |

| Used power source | AC220v×1.5KW |

| Machine Size | 1290×870×1280mm |

| Pack Size | 1120×920×1440mm |

| Weight | 450KG |

Haoly Machine

Haoly Machine