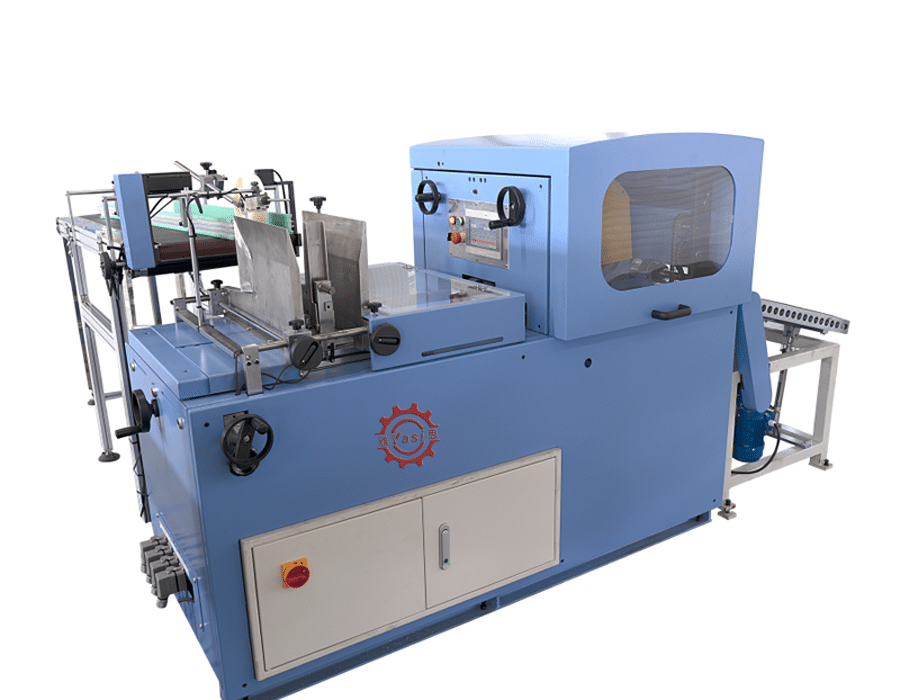

Machine Name: HL-FB-460 Dual-Book Splitting machine

Description:

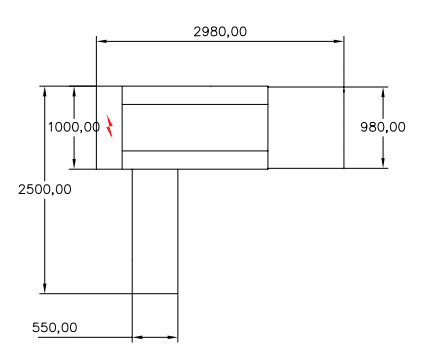

Equipment installation plan :

FB-460 splitting saw, for splitting two-up book blocks of perfect bound or thread sewn books and brochures. To be used in book production lines in front of a three knife trimmer. Equipped with infeed belt from right side or left side.

Product components:

- Infeed System: Comprising a conveyor belt and acceleration wheels, this system reliably and accurately transports the glued books into the machine’s storage hopper.

● Conveyance System: Books in the storage hopper are moved with a chain pusher and a synchronized belt, precisely delivering them to the circular saw cutting assembly.

● Splitting Assembly: Powered by a variable frequency drive motor and equipped with a circular saw, this assembly splits the twin books into individual units. It also features an optional side saw for more specialized cuts;

● Outfeed System: After splitting, the books are moved along a conveyor belt to the next stage of production.

Functions & features:

User-friendly Storage Hopper: This feature is reliable and easy to adjust. It can also be reoriented based on the layout of the customer’s site.

Versatility: The machine accommodates both fully bound books and semi-finished books with glued spines for twin-book splitting.

High-Powered Motor: Equipped with a high-speed, high-powered motor, the machine offers fast splitting speeds, minimal cutting errors, and optimal safety features.

Efficient Debris Collection: The machine uses an upper and lower debris suction method for effective waste collection. This allows for easy separation and recycling of paper edges and debris.

Technical Specifications:

Mechanical Speed: 1000-6000 books per hour Total Power: Approximately 14.75 kW

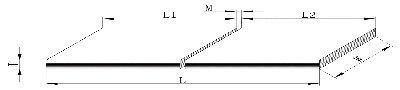

Single Blade Cutting Size:

| L | L1/L2 | W | T | M | |

| 最大尺寸max | 460mm | 230mm | 285mm | 60mm | 3mm |

| 最小尺寸min | 285mm | 140mm | 95mm | 5mm | 2mm |

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine