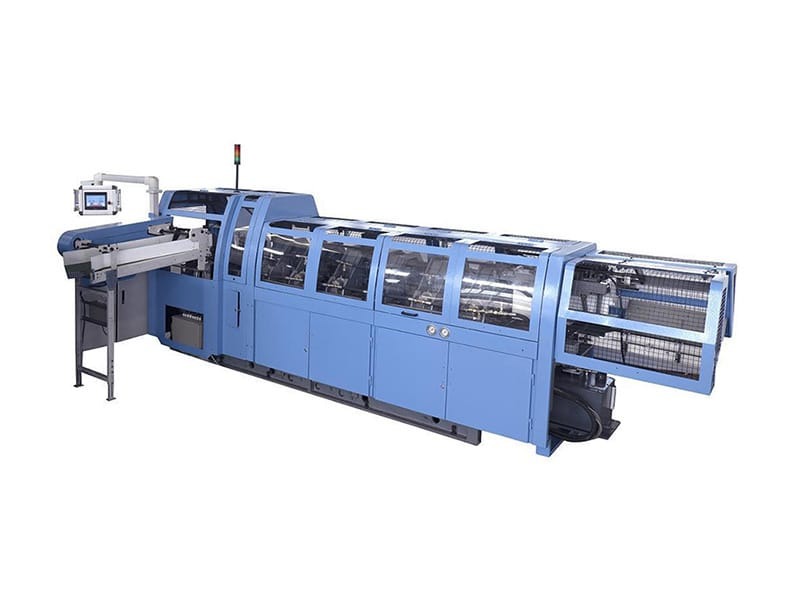

Machine Name: HL-RK-50 Book Pressing and Creasing Machine

Description:

Product Application :

Designed for fine hardback and softback books, this machine is used for the pressing and creasing operations after casing-in, enhancing the book’s appearance and making it easier to open and read. This effective mechanism aids in book pressing and creasing for refined results.

Components :

Components:The machine includes a control system, pre-positioning mechanism, book pushing mechanism, book conveying system, book pressing unit, groove hot pressing shaping mechanism, book discharge conveying system, book collection unit, and a hydraulic system.

Features :

- Storage and Memory: Capable of storing historical data for easy access and allows for the presetting and saving of new data.

● Automatic Adjustments: Input the dimensions of the cover and book thickness via a touchscreen. The servo drive system automatically adjusts multiple parameters such as book conveyor length, book pressing thickness, groove depth positioning, and book handling, offering convenience, precision, and high efficiency when changing specifications.

● Fault Detection: The machine halts and issues an alarm, displaying the fault when a malfunction occurs.

● Book Entry:Books that have been cased by the casing machine are sequentially fed onto the conveyor belt, held in place by an electromagnetically controlled stopper.

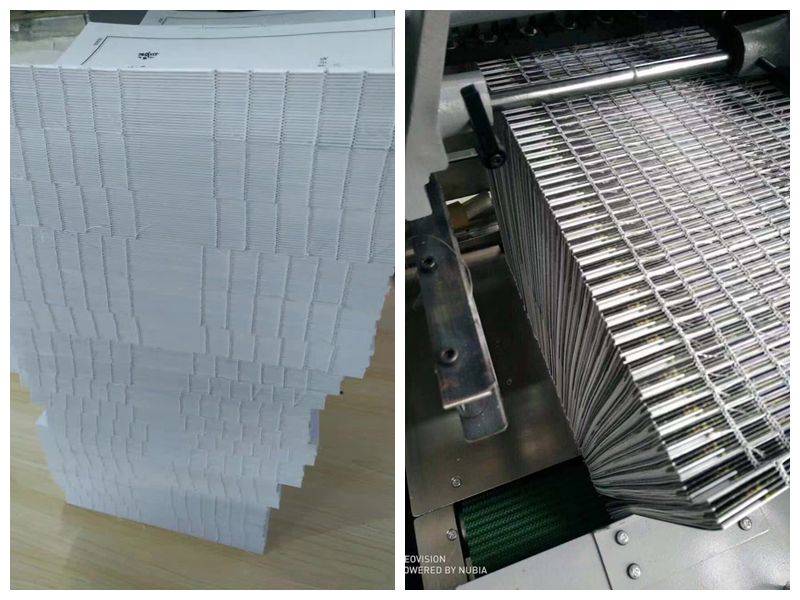

● Book Positioning:After release by the electromagnetic stopper, books enter the flipping station spine down, guided into position on the support tray by a book pusher rod, with precise width positioning by the pressing rod.

● Book Clamping:A clamping mechanical hand, powered by the hydraulic system,sequentially feeds the books into the working position.

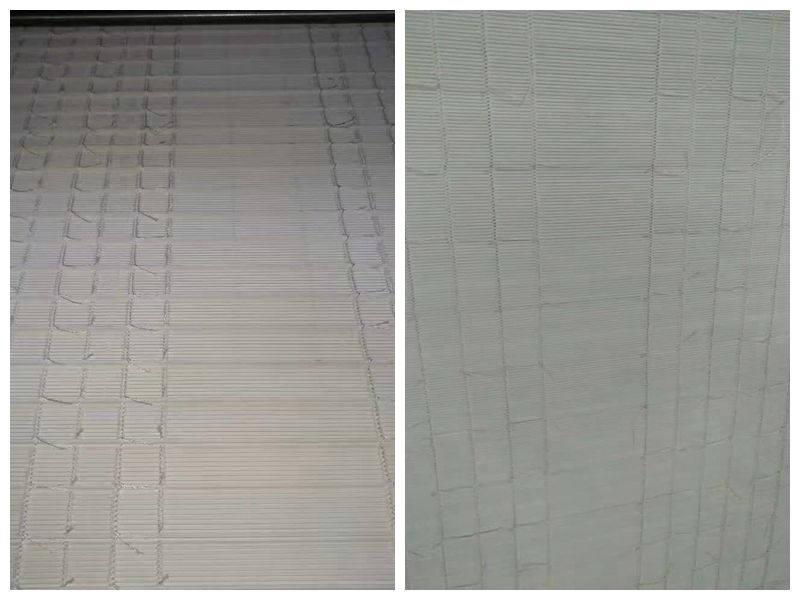

● Book and Groove Formation:The groove forming mechanism takes books for pressing and aids in the creasing process, performing six consecutive pressing and hot pressing cycles to shape the groove.

● Book Discharge:Finally, the discharge mechanical hand holds the finished books, placing them onto the discharge conveyor belt, completing the shaping and creasing process, enhanced by our advanced Book Pressing Creasing Mechanism.

● Hydraulic System:Provides the necessary power for book pressing and creasing, ensuring consistent pressure regardless of minor variations in book thickness.

● Automatic Lubrication:Features a timed and quantified automatic lubrication system, which ensures all major lubrication points receive oil during operation.

Technical Specifications:

|

Maximum Book Size

|

375×310 mm | Minimum Book Size | 135×100 mm |

|

Book Thickness Range

|

4-60mm | Maximum Mechanical Speed |

50 cycles/minute |

|

Minimum Book Core Size

|

4kw | Total Power | 19kw |

|

Voltage Requirement

|

380V | Frequency: | 50HZ |

|

Dimensions (L×W×H):

|

5780×2465×1755mm | Net Weight | 4200Kg |

Sample for Automatic Book Sewing Machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

We also provide machines like the Book Pressing Creasing Machine for various printing and packaging processes.

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine