Machine Name: HL-SX180/43 Automatic Book Sewing Machine, a prominent industrial book sewing machine.

Description:

Product composition:

The AUSCP SX180/43 consists of thread separating, paging, conveying, positioning, lockstitch, cutting, book separating, cutting head, and intelligent control systems. As a leading industrial book sewing machine, the AUSCP SX180/43 adopts an integrated design that does not require disassembly for relocation or transportation.

Functions & features:

- High speed and precision: maximum speed of up to 180 signatures per minute, with one fully sealed cam control box filled with lubricating oil for smooth and durable operation. As a high-performing industrial book sewing machine, the flywheel accurately drives paper feeding, conveying, and saddle stitching. The book signature on the saddle is precisely positioned through a synchronized belt structure with a puller.

● Intelligent debugging: Colored touchscreen monitors the entire production including paper feeding, conveying, lockstitching, and receiving, ensuring the quality of lockstitching.

● Fault detection & identifying: When faults such as missing signatures, multi-signatures, jams, dropped signatures, shortened signatures, and broken signatures occur, the machine will alarm and pause, while displaying the fault.

● Automatic mis-signature detection function (optional).

● Memory storage: can store 20 different book sewing programs and recall them as needed.

● Automatic plate adjustment: by setting the size of the signature on the touch screen and confirming the page-turning method, the transmission system automatically positions the conveyor belt, opens the page-turner, adjusts the position of the fixed saddle drive chain and acceleration wheel, and adjusts the height of the finished book platform. With this industrial book sewing machine, simple and easy to learn, fast operation, and quick plate switching improve production efficiency. Sorting: The hair dryer and mechanical arm separate the bottommost booklets from the booklet stack, and the gripper extracts the separated booklets from the feed hopper. The tilting device helps eliminate scratches on the surface of the booklets.

● Signature separation: the blower and mechanical arm separate the bottom signature from the pile, and the suction cup extracts the separated signature from the feeder. The tilting device helps eliminate scratches on the surface of the signature.

● Automatic page-turning: the page-turner is equipped with four programmable vacuum suction devices, both the upper and lower sides, which can perform 4+4 vacuum page-turning, and can handle signatures with even or uneven tops and bottoms. It can automatically flip through sets of pages, loose pages, pages without long or short edges, and unevenly thick signatures It can also turn pages of signatures with edges over 8mm long or short.

● Signature conveying: the signature is placed on the conveying saddle after being turned and is pushed by the conveyor chain hook. The acceleration wheel sends the signature into the active lockstitch saddle, and the speed of the acceleration wheel automatically adjusts according to the speed of the machine.

● Automatic signature separation and thread cutting: the automatic signature separation and thread cutting device (cuts the excess thread to about 8-10mm for easy binding) can separate the book signatures one by one according to the setting, regardless of the number of signatures in the book.

● Flat lock: uses fine ultra-short needles (¢16mm) with a narrow stitch spacing (19mm) to make the product flatter and less prone to glue leakage, ensuring high-quality book sewing. The lockstitch device consists of cam box type equipment, which not only reduces noise but also extends the life of the cam.

● Lubrication on demand: equipped with a centralized oil supply lubrication system, oil pressure alarm and oil storage device. When the machine is in operation, lubricant is precisely supplied through the pipe to wherever necessary in a timely manner.

Technical Data:

|

Max. operating speed

|

180 signatures/min | Min signature sewed | 2 signatures |

|

Max. signature size (H x L)

|

430x320mm | Page Turner Qty. | 4 top, 4 bottoms |

|

Min. signature size (H x L) |

120x75mm | Power consumption | 5kw |

|

Max. number of stitch positions |

10 | Standard voltage | 380V/ 220V 50Hz三相

400V, 50 Hz, 3 phases |

|

Stitch lenght

|

19 mm | Air consumption (external supply) | max. 1.0m3/min at 8bar |

|

Thread hook diameter |

¢1.6 mm |

Net weight

|

4500Kg |

|

Single signature thickness

|

0.5~1.5mm |

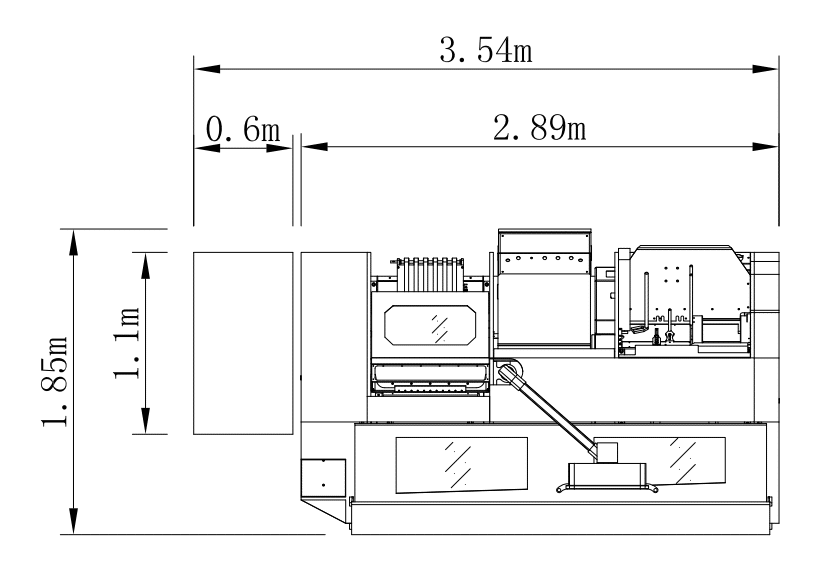

Dimensions (length x width x height) |

2890×1650×1850mm |

|

L H S Max. size 320 430 1.5mm Min. size 75 120 0.5mm

|

AUSCP SX180/43 | ||

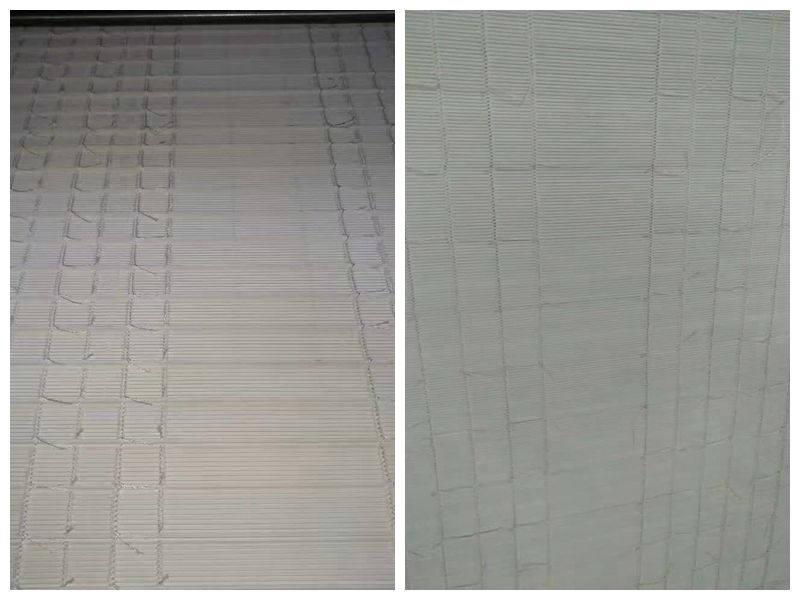

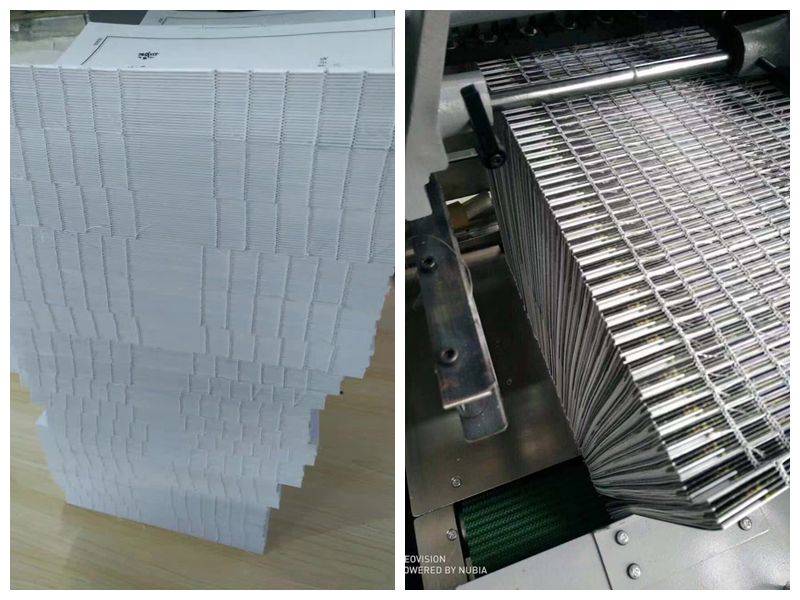

Sample for Industrial book sewing machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine. We offer industrial book sewing machines as part of our diverse range of products and are your best selection for printing and packaging industries.

In the past ten years, Lanxi Jinhua Machine Company is Focusing on machines for wire-stitched exercise books, ruled and sheeting, soft and hard cover book. They manufacture full automatic exercise book making machines, exercise book ruling machines, industrial book sewing machines, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machines.

we also can provide kinds of printing and packaging machines, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine