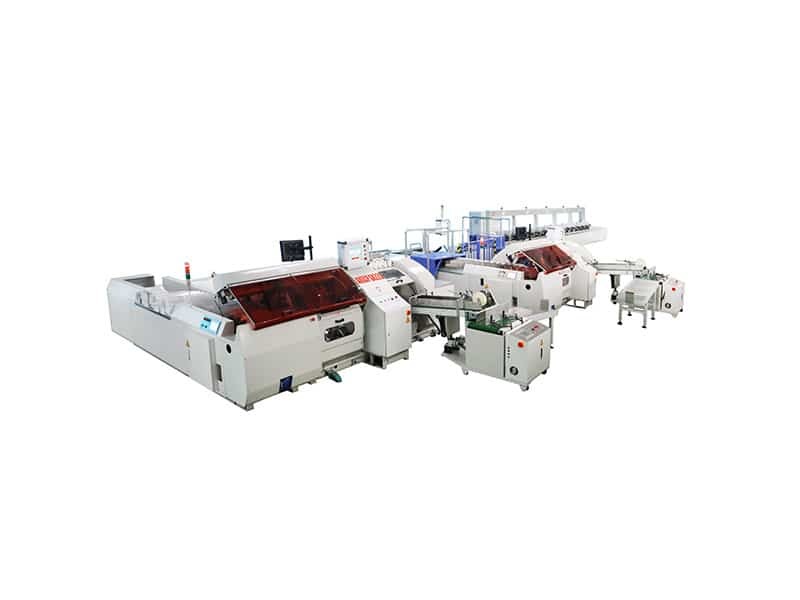

Machine Name: HL-PS-SX220-43 Fully automatic collating and sewing production line

Description:

Products

Consisting of one or two or three AUSCP (SX220/43, SX200/43, SX180/43) fully automatic thread locking machines in standard configuration and multiple sets of dosing stations AUSCP PY43 dosing machine linkage (up to 48 dosing stations can be connected, 15 dosing stations in standard configuration).

Design Concept

Page lock line linkage line is the fastest in the market at present page, lock line two processes in a production line to complete, is a perfect combination of automatic page machine and automatic locking machine; can be removed from the middle of the manual handling and storage of the link, saving the labor, save the site transit space, reduce the labor intensity of the workers to improve the efficiency of production and save the cost of production.

Functional features of the dispenser

- Intelligent control system, can be programmed through the menu, the machine comes standard with a rotary arm with a 12-inch color touch screen, which can control the operation of the machine running, alarm information, to facilitate the operator to discharge faults in a timely manner, the operation is convenient and easy to learn;

● The dispensing station is equipped with detection sensors for thick sticker, empty sticker, blockage, and conveyance, and has an indicator light display, which makes it easy to discharge the faults quickly;

● The page mating machine matches the book stickers of different page numbers together and stacks them to a height of 90mm, conveying them to the lane splitting station, which facilitates the conveyance of multiple locking line machines as required;

● The dubbing machine has a continuous start-up operation and emptying function, and feeds automatically according to the demand of the automatic thread locking machine without manual intervention.;

● Matching machine adopts roller-type lower posting design, is the book paste vertical operation, rapid operation of the book paste surface without friction;

● Conveying channel adopts roller type frictionless design to prevent rubbing the book pages and smooth conveying.;

● Storage lanes (tank chains) for each thread locker feed to facilitate on-demand feeding and automatic filling of time affected by mating machine downtime;

● Modular design, free combination, up to 48 page distribution stations;

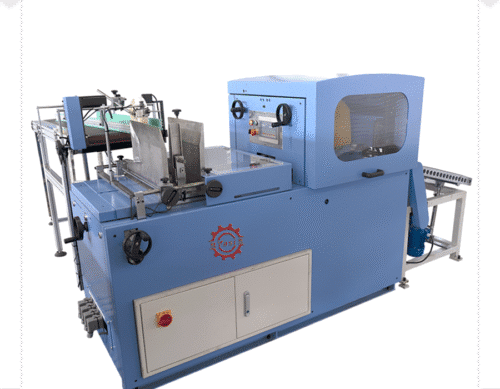

Functional features of thread locking machine

- High speed and high precision: the highest speed can be up to 220 stickers/minute, the whole machine has three fully sealed cam control box, the control box is filled with lubricating oil inside, the operation is equipped with a book stacker, which can stack the books with the locking line up to the height of 120mm, and convey them neatly to the book receiving table for palletizing;

● On-demand lubrication: centralized oil supply lubrication system, insufficient oil pressure can be alarmed, equipped with quantitative lubrication device, when the power on state, through the lubrication system to lubricate the need to lubricate the point to get quantitative lubricant;

Product Parameters

| 配页机组: | |||

| Max. mechanical speed | 6000 rpm per hour | Max. size (H x L) | 430x285mm |

| Paired posts | 12-48 posts | Min. size (H x L) | 148x90mm |

| 锁线机组: | |||

| Max. mechanical speed | 220 cycles/min | Min signature sewed | 2Post |

| Max. size(H x L) | 430x320mm | Available openings | 4 above, 4below +1 lap |

| Min. size (H x L) | 148x90mm | Needle diameter | ¢1.6 mm |

| Number of stitch positions | 10 groups | Single signature thickness | 0.5~1.5mm |

| Stitch lenght | 19 mm | ||

| 整机: | |||

| Rated power | 20kw | Air consumption (external supply) | max. 1.0m3/min at 8bar |

| Net weight | 8500Kg | Standard voltage | 380V/ 220V 50Hz三相 400V, 50 Hz, 3 phases |

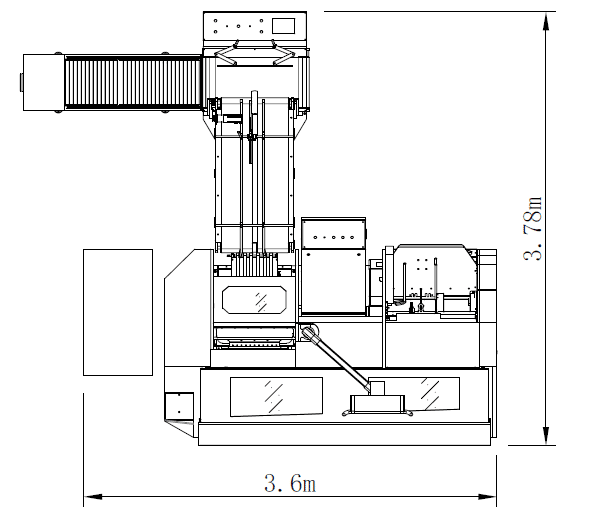

| Measures | 23410×4210×1850mm (配二台) 17610×4210×1850mm (配一台) |

||

| L H S Max. size 285 430 1.5mm Min. size 90 148 0.5mm |

AUSCP PS43 配页锁线联动线 | ||

Equipment Installation Plan

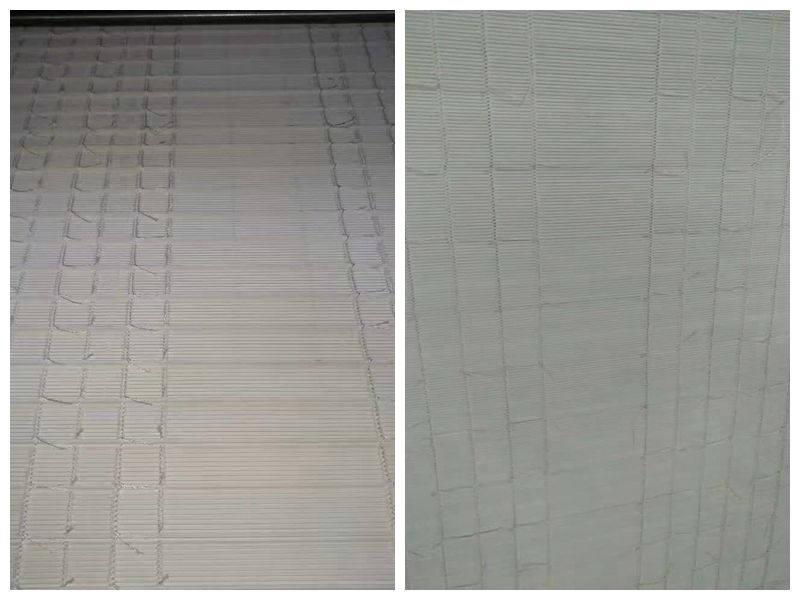

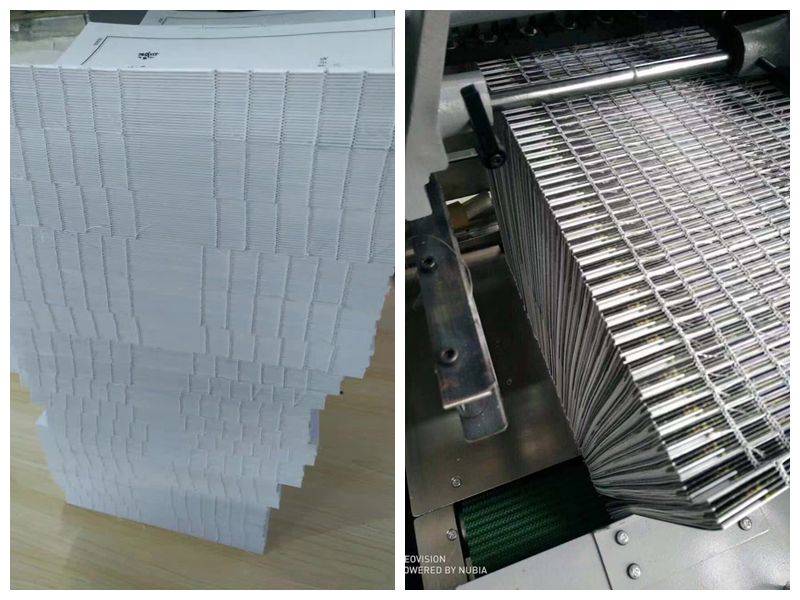

Sample for Automatic Book Sewing Machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine