Machine Name: HL-SD70 CNC High-speed Automatic Ribbon Inserting Machine (new version)

Description:

Product composition:

The entire machine uses a servo motor to drive the conveying mechanism, and the double-layer synchronized belt clamping system eliminates the need for intermittent transmission.

The servo-driven cutting function removes the need for manual cutting, improving the speed and efficiency of scissors.

The scissors-type cutting mechanism contains a heating curl function, which is more responsive and stable.

Can paste two ribbons simultaneously.

Product composition:

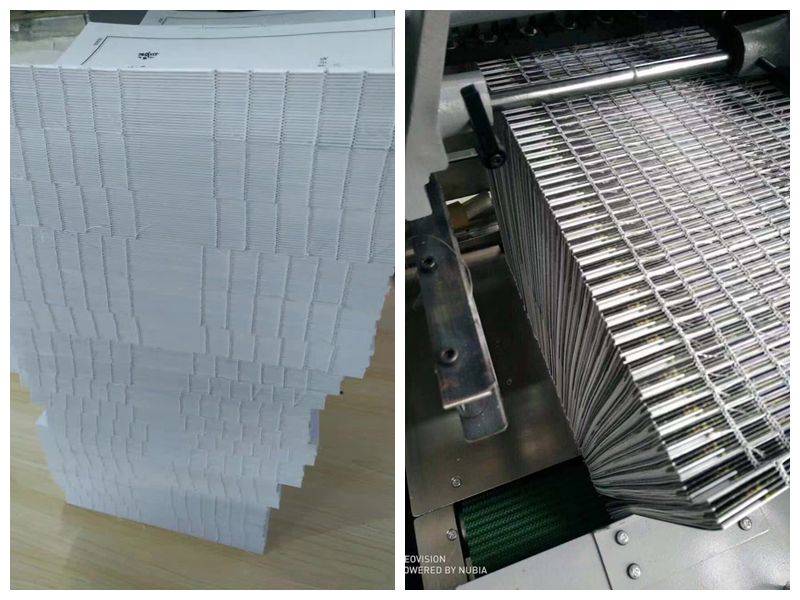

The machine is composed of a book core delivery mechanism, a synchronous belt clamping mechanism, a split-book delivery mechanism, a ribbon delivery mechanism, a ribbon back-folding mechanism, a ribbon cutter mechanism, a ribbon sticking mechanism, an output mechanism, etc.

Functions & features:

- The second-generation product by Yasi Machinery, the new version features improved performance by upgrading its structure as follows: ● The machine is controlled by a centre computer, which continuously unrolls the ribbon and then pastes it to book cores. The scissors with heating heads synchronize with the cutting ribbon, allowing for a fast and smooth cut. The cutting angle can be adjusted from vertical to diagonal.

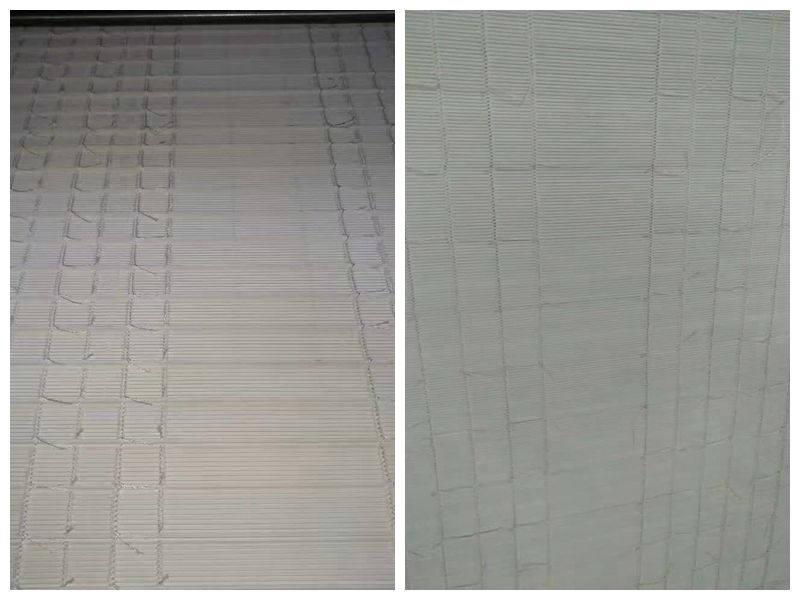

● The machine features ribbon back-folding, glue spray sticking, and automatic synchronous sticking functions.

● This machine is designed to work smoothly. No manual intervention required in a complete production cycle including book delivery, page turning, ribbon delivery, back-folding, cutting, etc.

● The machine can be used to paste ribbons for hardcover books, notebooks, account books, etc

● Can be linked with hardcover book machines to save labor costs and increase production efficiency.

● The machine adopts a compact, modular design that is stable and reliable.

● The intelligent control system allows speed settings to be programmed quickly and easily.

Technical Data:

|

Max. operating speed |

70 book blocks per minute |

Power consumption | 4.5kw |

|

Max. book block size

|

285x297mm | Standard voltage | 380V 220V 50Hz |

|

Min. book block size

|

150x100mm | Air consumption (external supply) | 0.35 m3 /分钟 0.35 m3 /min 8 bar |

|

Min. book thickness

|

8mm |

Net weight |

2500kg |

|

Max. book thickness

|

60mm |

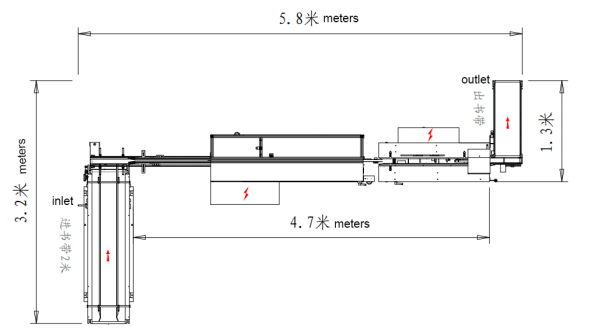

Dimensions (length x width x height)

|

5800x 3200 x 1900mm |

|

The ribbon width

|

4-10mm | ||

|

L H S Max. size 297 285 60mm Min. size 100 150 8mm

|

AUSCP SD 70 | ||

Sample for Automatic Book Sewing Machine

Video

About us

Zhejiang Haoly Limited combines extremely competitive price, innovative technologies and long-standing exporting experience in the Post press machine, printing machine,and packaging machine, and quick printing machine.We are your best selection for printing and packaging industries.

In past ten years, Lanxi Jinhua Machine Company is Focusing on machine for wire-stitched exercise books, ruled and sheeting, soft and hard cover book.Can manufacture full automatic exercise book making machine, exercise book ruling machine, book sewing machine, casing in machine, hard cover making machine, three side trimmer, saddle stitching machine, glue binding machine, and other post press machine.

we also can provide kinds of printing and packaging machine, such as

1. Post press machine: paper cutting machine, laminating machine, creasing and die cutting machine, hot stamping machine, paper folding machine, paper collating machine, paper punching machine, eyelet machine

2. Printing Machine: Offset printing machine, Pre-press machine, Flexo Printing machine, card printing machine

3. Quick printing machine: small paper cutter, digital Creasing machine, small glue binding machine.

4. Paper product making machine: gluer folder, paper box machine, paper bag machine, paper cup machine, envelope making machine

We are an actual factory and manufacturer with trading in the line of postpress machine and package machines for more than 10 years.

1. 30 years of production experience with good quality. All our machines have got CE certificate.

2. Competitive price in the same level quality of paper cutting machines.

3. Thoughtful pre-sale and after-sale service. Any questions, pls feel free to contact us.

For most orders, payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery. And we also accept other way like L/C, wetern union etc.

1. Uauslly ,most machine is stable and easy to operate, With the help of videos and instructions, you can quickly learn how to operate.

2. If still cannot operate, We offer online training and video instruction

3. If you need to dispatch an engineer, please contact us for detailed consultation

Haoly Machine

Haoly Machine